Microfocus X-ray systems are advanced X-ray imaging systems that utilise a microfocus X-ray source to produce high-resolution images. Microfocus systems are widely used in various industries for non-destructive testing, quality control, and inspection applications where detailed imaging of small features is required. Unlike conventional X-ray systems with broad focal spots, microfocus X-ray systems feature X-ray tubes with extremely small focal spots, typically less than 5 micrometers in sise. This enables them to produce highly detailed images with excellent spatial resolution.

Microfocus X-ray systems are capable of high magnification imaging, allowing users to inspect small features and components with exceptional clarity and detail. This makes them suitable for applications where fine defects or structures need to be analysed. These systems often offer adjustable resolution settings, allowing users to balance between image resolution and inspection speed based on their specific requirements. Higher resolutions result in finer details but may require longer acquisition times.

Microfocus X-ray systems employ a variety of techniques, including computed tomography, planar tomography and high resolution x-ray microscopy, servicing a wide variety of applications and industries.

X-Ray Microfocus Applications

Electronic Components Inspection

Microfocus X-ray systems are widely used in the electronics industry for inspecting printed circuit boards (PCBs), semiconductor packages, connectors, and other electronic components. They can identify defects such as solder joint voids, wire bonds, and component misalignment.

Medical Device Inspection

These systems are employed for inspecting medical devices such as implants, catheters, and electronic assemblies. They can detect manufacturing defects, verify component integrity, and ensure compliance with regulatory standards.

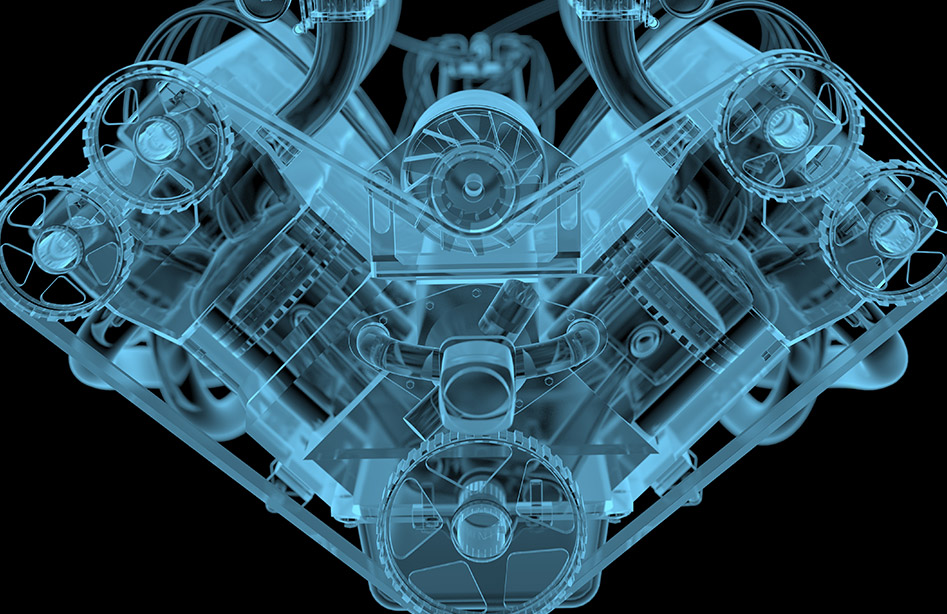

Aerospace and Automotive Components

Microfocus X-ray systems are used to inspect critical components in the aerospace and automotive industries, including turbine blades, engine components, welds, and castings. They can detect defects such as porosity, cracks, and voids that may affect structural integrity and performance.

Materials Science and Research

Microfocus X-ray systems are valuable tools in materials science research for studying the microstructure, composition, and properties of materials. They can visualise internal features such as grain boundaries, inclusions, and defects in various materials, including metals, ceramics, composites, and polymers.

Art Conservation and Archaeology

These systems are used in art conservation and archaeology for non-destructive analysis of cultural artifacts, historical objects, and archaeological specimens. They can reveal hidden features, structures, and manufacturing techniques without damaging the artifacts.

Gulmay Generators for the Microfocus Industry

Gulmay has earned a unique place in the development of the microfocus x-ray inspection technique. In 1982, Gulmay became the world’s first x-ray generator manufacturer to provide a dedicated power supply solution to meet the unique requirements presented by demountable x-ray tubes.

Working closely with microfocus tube manufacturers globally, Gulmay continues to develop innovative enhancements to its microfocus x-ray generator product range. The new, patented Resonant Filament drive system offers accurate filament current monitoring and has been demonstrated to improve filament lifetime by more than 70% in filament lifetime compared with standard microfocus filament technology according to laboratory tests.*

*patent number US11,751,316B2.

Other Microfocus XRay Applications

Microfocus Generators

Gulmay’s Microfocus generator line up has grown to include generators ranging from 65kV up to 320kV. Read More