X-ray technology has found diverse applications in metrology and calibration across various industries due to its ability to provide non-destructive inspection, precise measurements, and accurate calibration including the following x-ray metrology and calibration applications.

X-Ray Metrology and Calibration Applications

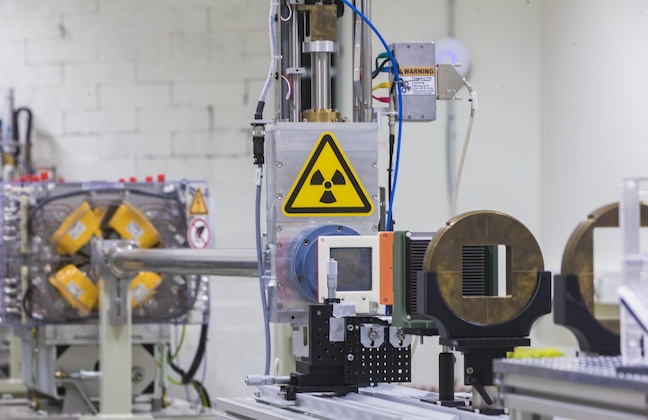

Dimensional Metrology

X-ray imaging allows for the measurement of internal and external dimensions of complex components without the need for disassembly. This is particularly valuable in industries such as automotive, aerospace, and electronics, where intricate parts require precise measurements.

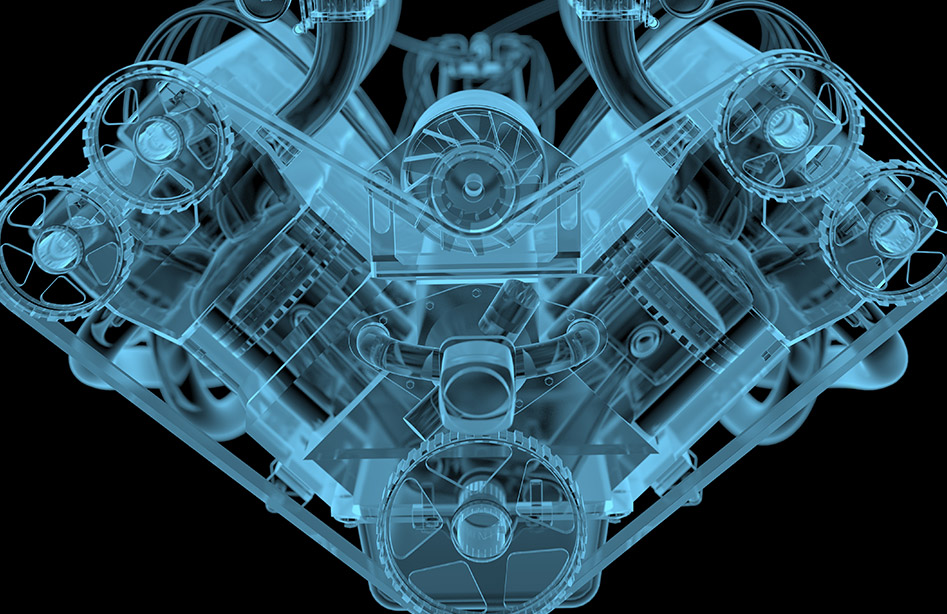

Surface Metrology

X-ray techniques can be used to analyse surface morphology and roughness with high precision. This is crucial for ensuring the quality and functionality of components in applications where surface characteristics are critical, such as in medical devices or semiconductor manufacturing.

Defect Detection and Analysis

X-ray inspection enables the detection and analysis of defects such as voids, cracks, porosity, and inclusions in materials and components. By identifying these defects early in the manufacturing process, companies can prevent costly rework or product failures.

Material Analysis

X-ray fluorescence (XRF) analysis is used for elemental and chemical analysis of materials. This technique helps verify material composition, detect impurities, and ensure compliance with regulatory standards in industries such as pharmaceuticals, mining, and metallurgy.

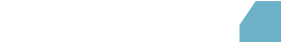

Calibration of X-ray Equipment

X-ray sources, detectors, and imaging systems require regular calibration to ensure accurate and reliable measurements. X-ray calibration standards are established and maintained to trace measurements back to internationally recognised units, ensuring consistency and reliability in metrology applications.

Quality Control in Additive Manufacturing

X-ray computed tomography (CT) is widely used for quality control in additive manufacturing (3D printing). CT scans provide detailed 3D images of printed parts, allowing manufacturers to verify dimensional accuracy, detect defects, and assess internal structures without destructive testing.

Metrology in Electronics Industry

X-ray metrology is extensively used in the electronics industry for inspecting solder joints, wire bonds, and electronic components. X-ray imaging techniques help ensure the reliability and functionality of electronic devices by detecting defects such as voids, cracks, and misalignments.

Other NDT XRay Applications

Other Microfocus Xray Inspection Applications

Gulmay Generators for the Metrology Industry

UC Series X-ray Generators

Gulmay’s Microfocus generator line up has grown to include generators ranging from 65kV up to 320kV. Read More

DT-225

The DT-225 high volatage divider tank is designed for precision measurement of any high voltage generator output.